![]() Home > News

Home > News

Source:https://www.aircraft-aluminium.com/a/what-are-military-grade-aluminum-alloy.html

Military grade aluminum alloys are aluminum alloys developed to meet the requirements of military equipment (such as combat aircraft, armored vehicles, missiles and ships). Key requirements include high strength, lightweight, adaptability to extreme environments (such as high and low temperatures, corrosion, shock and vibration), and structural reliability. Furthermore, they must be compatible with the operational scenarios of military equipment (such as battlefield maintainability and damage resistance).

Typical military grade aluminum alloy types (using mainstream models from China, the US, and Russia as examples):

1. 2000 series aluminum alloys (Al-Cu-Mg series, hard aluminum alloys):

- Representative types: 2A12 (China), 2024 (US).

- Features: Medium strength (tensile strength approximately 420-480 MPa), but excellent toughness, fatigue resistance, and weldability, making them suitable for components subjected to alternating loads, such as military aircraft fuselages and armored vehicle hulls.

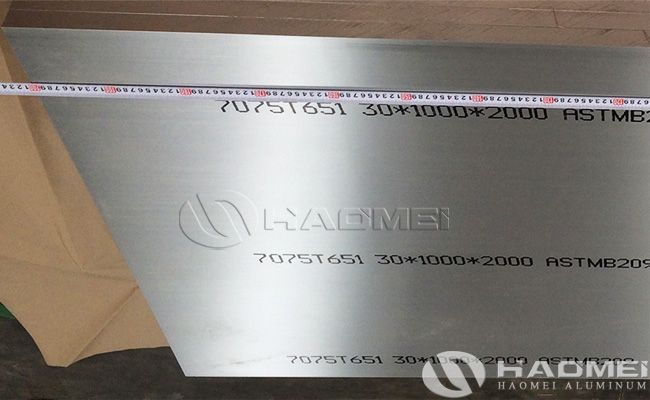

2. 7000 series aluminum alloys (Al-Zn-Mg-Cu series, super-hard aluminum alloys):

- Representative types: 7A04 (China, corresponding to US 7075), 7050 (US).

- Features: Extremely strong (tensile strength can reach 550-650 MPa), it is one of the strongest aluminum alloys currently available and is suitable for manufacturing heavy-duty or impact-resistant components such as missile bodies, military aircraft landing gear, and armored vehicle fenders.

3. 5000 Series Aluminum Alloy (Al-Mg series, rust-resistant aluminum alloy):

- Representative model: 5083 (used in both China and the United States).

- Features: Extremely corrosion-resistant (especially seawater), with medium strength (approximately 300-350 MPa), suitable for manufacturing naval vessel decks and amphibious equipment hulls.

Aerospace grade aluminum alloys (primarily used in civil airliners and transport aircraft) share core requirements with military grade aluminum alloys (such as lightweight and high strength), but their performance priorities differ significantly due to their diverse application scenarios.

1. Similarities:

- Both share the same core objective: "high strength + low density." They enhance mechanical properties through alloying (additions of Cu, Mg, Zn, and Mn, among others) and heat treatment (such as age hardening) to meet structural weight reduction requirements (aluminum alloy density is approximately 2.7g/cm³, only one-third that of steel).

- Basic performance requirements overlap: both require a certain level of corrosion resistance (to avoid oxidative corrosion in high-altitude/marine environments), formability (such as forging, rolling, and welding), and structural stability (to avoid dimensional changes during long-term use).

2. Differences:

- Performance Emphasis

Military grade aluminum alloys prioritize reliability in extreme environments (such as -50°C to 150°C temperature fluctuations, battlefield shock/vibration, and shell fragment impact) and damage resistance (high strength and hardness).

Aviation grade aluminum alloys prioritize fatigue life (to withstand the cyclical loads of tens of thousands of takeoffs and landings on passenger aircraft) and fracture toughness (to avoid sudden structural fractures at high altitudes).

- Cost Sensitivity

Military grade aluminum alloys have a high tolerance for cost (military equipment production is low, prioritizing performance).

Aviation grade aluminum alloys are even more cost-sensitive (civil aircraft production is high, requiring a balance between performance and manufacturing cost).

- Environmental Adaptability

Military grade aluminum alloys must adapt to complex battlefield environments (such as desert dust, ocean salt spray, and battlefield oil contamination), requiring a broader spectrum of corrosion resistance.

Aviation grade aluminum alloys are primarily suited to high-altitude atmospheric environments (low pressure, ozone corrosion), requiring more specific corrosion resistance (such as resistance to atmospheric oxidation).

- Certification Standards

Military grade aluminum alloys adhere to military standards (such as China's GJB and US MIL standards), emphasizing combat validation (such as live-fire testing).

Aviation grade aluminum alloys adhere to aviation airworthiness standards (such as China's CCAR and US FAA), emphasizing long-term reliability (such as tens of thousands of hours of fatigue testing).

- Typical Applications

Military grade aluminum alloys are used in armored vehicles, missiles, aircraft landing gear, and ship decks.

Aviation grade aluminum alloys are used in civil aircraft fuselages, wing skins, and engine nacelles.

Both military grade and aviation grade aluminum alloys are high-performance aluminum alloys, but military grade aluminum alloy emphasizes damage resistance and reliability in extreme scenarios, while aviation grade aluminum focuses on fatigue safety under long-term cyclic loading. While there is overlap in material systems between the two (e.g., 7075 and 2024 are used in both military and civil aircraft), they utilize distinct heat treatment processes and quality control standards to meet the core requirements of their respective applications.