![]() Home > News

Home > News

Source:https://www.aircraft-aluminium.com/a/aircraft-aluminum-plate-7075-t6-t651-t7351.html

7075 aluminum alloy is a super-hard aluminum material commonly used in the aerospace, military and high-load structures field due to its high strength. Different heat treatment states (such as T6, T651, T7351, etc.) will affect the performance of 7075 aircraft aluminum plate.

Differences in heat treatment process and performance

1. 7075-T6 aircraft aluminum plate

- Process: Direct artificial aging (T6 state) after solid solution treatment to improve strength by precipitation strengthening phase.

- Performance:

High strength: tensile strength can reach more than 560MPa, yield strength exceeds 495MPa, and hardness is about 150HB.

High hardness: suitable for bearing high stress loads, but weak resistance to stress corrosion cracking (SCC).

- Application: aircraft wing beams, fuselage frames, high-strength molds and other structural parts with extremely high strength requirements.

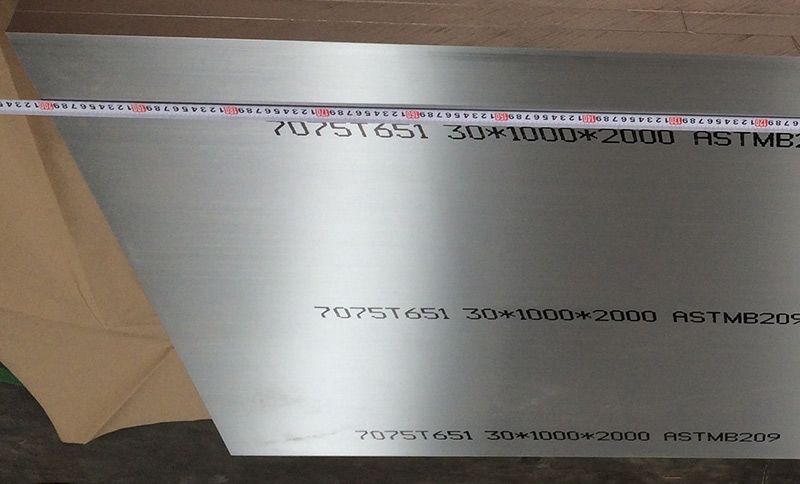

2. 7075-T651 aircraft aluminum plate

- Process: Add a tensile stress relief process based on T6 to reduce internal residual stress by pre-stretching.

- Performance:

Dimensional stability: not easy to deform after processing, suitable for precision processing (such as aviation landing gear parts).

Strength and corrosion resistance balance: strength is close to T6 (tensile strength 560MPa+), corrosion resistance is slightly better, but still inferior to T7351.

- Application: aircraft main load-bearing structure (such as wing ribs, stringers), high-end sports equipment (such as bicycle frames) and high-precision molds.

3. 7075-T7351 aircraft aluminum plate

- Process: adopt double-stage aging treatment to optimize the distribution of precipitation phase to improve stress corrosion resistance.

- Performance:

Corrosion resistance advantage: significantly better than T6 and T651, suitable for humid or salt spray environment.

Strength retention: tensile strength of about 524MPa, yield strength of 455MPa, elongation of 11%, and balanced comprehensive performance.

- Application: marine engineering equipment, chemical machinery, aerospace parts that need to take into account both strength and corrosion resistance (such as fuel system components).

Selection Basis of different tempers of aircraft aluminum 7075:

- Strength priority: Choose T6, which is suitable for high-load scenarios without corrosion risk (such as aircraft beams).

- Precision and stability: Choose T651, which is suitable for parts that require complex processing and small deformation (such as aircraft engine brackets).

- Corrosion resistance key: Choose T7351, which is used in coastal areas or equipment that contacts corrosive media (such as carrier-based aircraft landing gear).

- Processing cost: T651 has a slightly higher cost than T6 due to the addition of stress relief process; T7351 has the highest cost due to the two-stage aging process.

Typical application cases

- T6: Boeing 737 fuselage frame, F-16 fighter wing stringers.

- T651: Airbus A350 landing gear components, high-end drone structural parts.

- T7351: Offshore platform lifting equipment, aviation fuel pipeline joints.

The selection of 7075-T6, T651, and T7351 aircraft aluminum plate requires comprehensive consideration of strength, corrosion resistance, processing accuracy, and cost. T6 is suitable for extreme strength requirements, T651 balances strength and stability, and T7351 excels in corrosion resistance. In the aerospace field, the choice is often flexible based on the service environment of the components (such as high-altitude dryness, ocean wetness) and load characteristics to ensure the best match between safety and economy.